DOWNLOADS

Low MOQ for Steel Belt Cooler - Chemical Pastillating Machine – Mingke Detail:

CHEMICAL PASTILLATING MACHINE

Besides steel belts, Mingke can as produce and supply steel belt type Chemical Pastillating Machine.

Pastillating machine manufactured by Mingke is equipped with Mingke products. Such as brand high strength steel belts, rubber r-ropes and steel belt tracking systems.

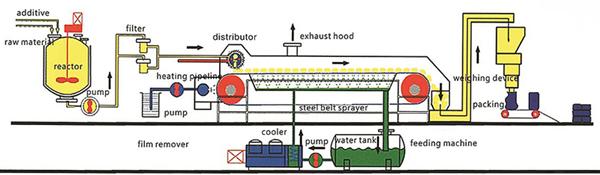

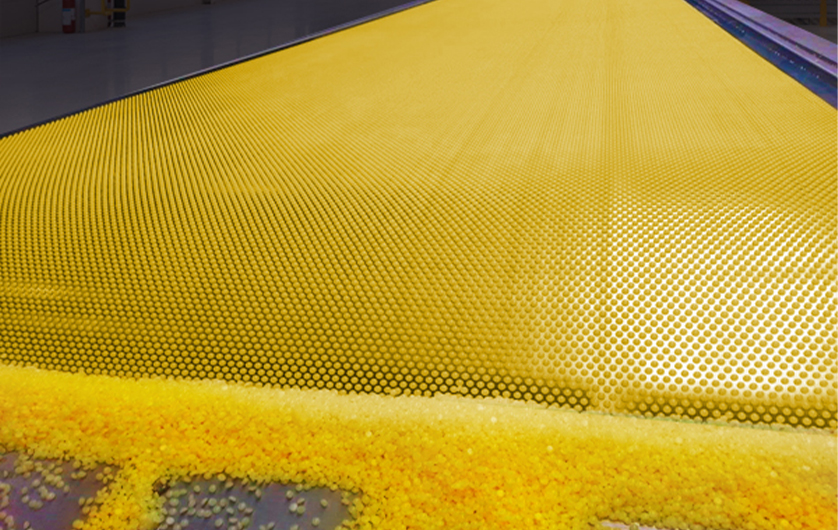

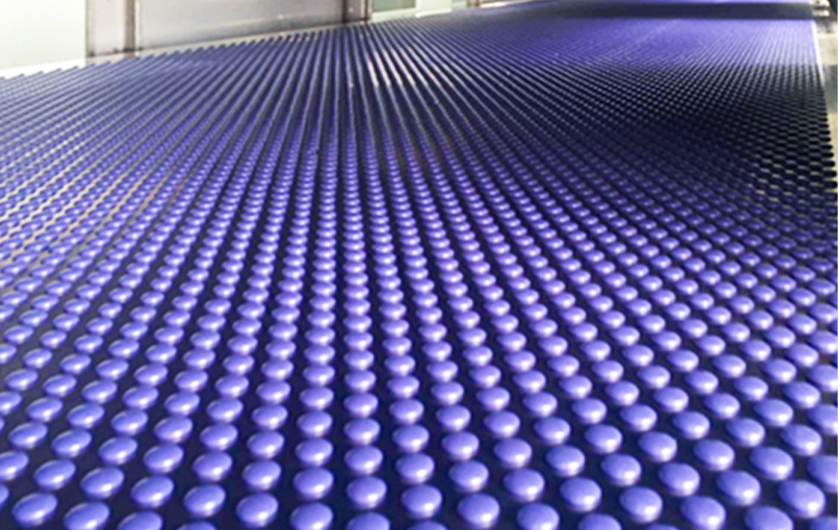

Steel belt cooling pastillator is a kind of melt granulation process equipment. Molten materials drop evenly onto the steel belt which is moving at a uniform speed. Due to cold water spraying onto the back side of the belt, the molten materials are cooled down & solidified quickly and finally achieve the purpose of pastillating.

Work Principle

Steel belt cooling granulator, by the distributor, makes the fusing materials from the upstream process drop evenly on the steel belt moving a constant speed underneath. There is a water return device under the steel belt which can spray cooling water to cool and solidify the fusing material during the course the material is moving, achieving the aim of granulation.

Main Parameters

| Model | Belt width (mm) | Capacity (Kg/h) | Power (Kw) | Length (m) | Weight (Kg) |

| MKZL-600 | 600 | 100-400 | 6 | 18 | 2000 |

| MKZL-1000 | 1000 | 200-800 | 10 | 18 | 4500 |

| MKZL-1200 | 1200 | 300-1000 | 10 | 18 | 5500 |

| MKZL-1500 | 1500 | 500-1200 | 10 | 18 | 7000 |

| MKZL-2000 | 2000 | 700-1500 | 15 | 20 | 10000 |

Applications of Chemical Pastillator

Paraffin, sulfur, chloroacetic acid, PVC adhesive, PVC stabilizer, epoxy resin, ester, fatty acid, fatty amine, fatty ester, stearate, fertilizer, filler wax, fungicide, herbicide, hot melt adhesive, refined productsfilter residue, rubber, rubber chemicals, sorbitol, stabilizers, stearates, stearic acid, synthetic, food adhesives, synthetic catalysts, bitumen tar, surfactants, elixirs, urea, vegetable oil, vegetable wax, mixed wax, wax, zinc nitrate, zinc stearate, acid, anhydrite, additive, adhesive, agrochemical, AKD-wax, aluminum nitrate, ammonium phosphate, antioxidant, anti-fermentation, asphalt alkene, thermoplastic base, beeswax, bisphenol A, calcium chloride, caprolactam, catalyst, cobalt stearate, cosmetics, hydrocarbon resin, industrial chemistry, medium, maleic anhydride, crystal wax, sulfur product, nickel-catalyst, Insecticides, PE-wax, medical media, photochemicals, asphalt, polyester, poly-ethylene glycol, polyethylene wax, polypropylene, polyurethane, others.

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Low MOQ for Steel Belt Cooler - Chemical Pastillating Machine – Mingke , The product will supply to all over the world, such as: Italy, Congo, Mauritius, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.