DOWNLOADS

18 Years Factory Stainless Steel Belt - The Type Of Chemical Flaking Machine – Mingke Detail:

CHEMICAL FLAKING MACHINE

Besides steel belts, Mingke can also manufacture and supply Chemical Flaking Machine.There are 2 types of flaking machine: single belt flaker and double belt flaker.

Flake machine manufactured by Mingke is equipped with Mingke products. Such as high strength steel belts, rubber r-ropes and steel belt tracking systems.

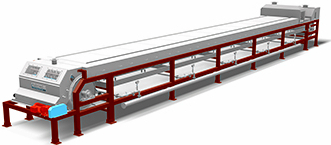

Single Belt Flaker

The molten material enters the distribution device through the heat tracing pipe and continuously overflows onto the upper side of the running steel belt from the distributor. With the excellent heat transfer characteristics of the steel belt, the material forms a thin layer on the steel belt and being cooled down and turns into solid flake by water sprayed onto the back side of the belt. The cooled flake is scratched down from the steel belt by a scraper and then crushed by crusher into set sizes.

Main Parameters

| Model | Belt width(mm) | Power(Kw) | Capacity(Kg/h) |

| MKJP-800 | 800 | 4-6 | 200-500 |

| MKJP-1000 | 1000 | 8-10 | 500-800 |

| MKJP-1200 | 1200 | 10-12 | 800-1100 |

| MKJP-1500 | 1500 | 12-15 | 1100-1400 |

| MKJP-2000 | 2000 | 15-18 | 1400-1600 |

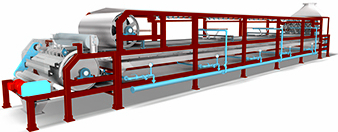

Double Belt Flaker

The molten material enters the distribution device through the heat tracing pipe and continuously overflows into the gap between running upper and lower steel belts from the distributor. With the excellent heat transfer characteristics of the steel belts, the material is cooled down and turns into solid flake by water sprayed onto the back sides of the belts. The cooled flake is scratched down from the steel belt by a scraper and then crushed by crusher into set sizes.

Applications of Chemical Flaker

Epoxy resin, sulfur, paraffin, chloroacetic acid, petroleum grease, stone carbonate, pigment, polyamide, polyamide grease, polyester, polyester resin, polyethylene, polyurethane, polyurethane resin, acid, anhydride, acrylic Resin, fatty acid, alkyl sulfide, aluminum hydroxide, aluminum sulfate, irregular acrylic acid, vinyl acetonitrile, organic fatty acids, fatty amines, stearates, food chemistry, hydrocarbon resins, industrial chemistry, magnesium chloride, magnesium nitrate, chlorine Compound, petroleum cobalt, hydrazine, potassium nitrate, potassium sulfate, powder coating, powder coating, refined product, filter residue, resin, molten salt, silica gel, sodium nitrate, sodium sulfide, sulfur, toner, chemical waste, Wax, monomer, adhesive, coating, p-dichlorobenzene, others.

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is You come here with difficulty and we provide you with a smile to take away for 18 Years Factory Stainless Steel Belt - The Type Of Chemical Flaking Machine – Mingke , The product will supply to all over the world, such as: Costa rica, Haiti, Guyana, Due to the stability of our products, timely supply and our sincere service, we are able to sell our products not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.