With the accelerated development of the hydrogen energy industry, mass production of carbon paper—one of its core components—still faces significant challenges. As a domestic partner with proven delivery capabilities, Mingke focuses on the continuous curing and forming stage of the production line. Leveraging its double steel belt isostatic press technology, Mingke helps customers overcome key bottlenecks in achieving large-scale production.

Across the globe, hydrogen energy is widely discussed as a key carrier of clean energy. However, when we shift our focus from the grand vision to the realities of the production line, significant challenges remain:

Thickness variation: In conventional pressing processes, uneven pressure distribution can easily lead to inconsistent density in carbon paper.

Efficiency bottlenecks: Intermittent production methods struggle to meet the future surge in delivery demand driven by the rapid expansion of the hydrogen energy industry.

Yield challenges: Large fluctuations in the process window increase trial-and-error costs as well as material losses.

At this critical juncture, Mingke offers a stable, precise and continuous curing solution for the production line ——

Isostatic double belt press

Imagine a “mobile tunnel” of high temperature and high pressure created by a double steel belt system. Within this tunnel, fluid-based Pascal’s law is applied to simulate deep-sea hydrostatic pressure. This means that regardless of where the carbon paper is positioned on the conveyor, the material is subjected to full-surface contact pressure—uniform, omnidirectional, and free of dead zones.

This technical feature has brought about substantial changes to the production of carbon paper:

1. Protect the microstructure and enhance consistency

Through fluid-based isostatic pressure, thickness deviations commonly caused by conventional mechanical presses are effectively minimized. Isostatic pressing helps preserve the integrity of the substrate structure during resin curing, enabling the final carbon paper to achieve a high level of consistency in both thickness and pore structure.

2.Precise Temperature Control for Optimal Process Parameters

Resin curing in carbon paper production is extremely sensitive to temperature. Mingke’s double steel belt isostatic press supports continuous operation at temperatures of up to 400 °C. In addition, it is tailored to different process requirements and incorporates multi-zone independent temperature control, enabling segmented and precise regulation of the temperature profile in accordance with the specific curing characteristics of the resin.

3. Enabling Production Ramp-Up and Reducing Hidden Costs

By enabling the transition from intermittent to continuous production, Mingke’s press significantly improves overall manufacturing efficiency. At the same time, its highly stable process minimizes scrap caused by equipment fluctuations, helping customers substantially reduce material losses during the production ramp-up phase.

Not only equipment, but we also offer one-stop solutions

Continuous curing of carbon paper depends not only on a single press but on the seamless coordination of the entire production line. Mingke understands the challenges customers face in multi-equipment integration and interface commissioning. Therefore, we go beyond delivering the core isostatic press and are fully capable of providing complete upstream and downstream tooling and equipment for the entire continuous carbon paper curing process.

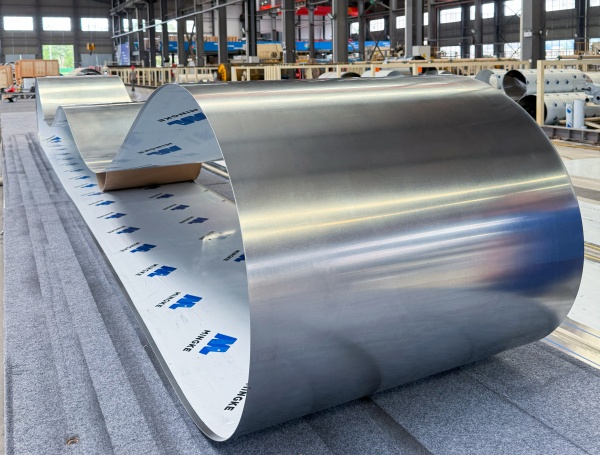

At the same time, to address the common issues of phenolic resin sticking and difficult cleaning after curing, we recommend using chrome-plated steel belts. The dense chrome layer offers high hardness and wear resistance, while its surface oxide film effectively prevents corrosion. Acting as a strong “barrier layer,” it makes excess resin cleanup much easier and reduces reliance on costly release agents or release papers, delivering cost savings and efficiency improvements for customers down to the smallest details.

As a domestic partner with mature delivery capabilities, Mingke has been deeply engaged in the composite materials industry for ten consecutive years and has successfully assisted nine clients in achieving mass production and application of composite materials. We not only offer cost-effective domestic alternative solutions, but also promise a 24-hour response and on-site engineers within 48 hours.

From laboratory samples to full-scale production, there lies a vast gap. Mingke exists to build that solid bridge. Whether you are focused on hydrogen fuel cell carbon paper or engaged in solid-state batteries or composite materials, if you aim to achieve a leap in your forming process—from intermittent to continuous, from manufacturing to intelligent manufacturing—Mingke’s double steel belt isostatic press is the trusted solution you can rely on.

Want to verify it yourself?

The Mingke Nanjing factory currently has two double steel belt static isobaric testing machines, which are now open as mass production-level testing platforms. We also offer small-batch contract manufacturing services to help you validate the process at low risk and minimal cost!

Post time: Jan-09-2026